DTF adhesive powder, is one of the key components in the DTF printing process. It acts as a binding agent that allows the printed design to adhere permanently to the fabric during heat pressing. The powder is thermally activated – it melts under heat and forms a flexible yet strong bond with the material. It is primarily made from polyurethane resin, additives, and pigments, and then ground into a fine adhesive powder. High-quality white DTF powder is made from pure polyurethane and features medium adhesive strength, making it suitable for a wide range of applications.

There are three main types of powders used in DTF printing: TPU, PES, and PA. TPU (Thermoplastic Polyurethane) is the most commonly used powder, known for its flexibility and abrasion resistance. It is ideal for sportswear and stretchable fabrics, as it gives the print durability, stretchability, and a soft hand feel that doesn’t crack when the fabric moves. PES (Polyester powder adhesive) offers a stiffer finish and excellent wash resistance, making it the preferred choice for designs where durability is a priority, especially for garments made of polyester. PA (Polyamide, also known as nylon) combines the strengths of TPU and PES, providing a good balance between elasticity and durability. This makes it suitable for a wide range of applications where the print must be both long-lasting and flexible, while also resisting wear and tear.

How Hand Powdering Works

Hand powdering is a manual method used in DTF printing to apply adhesive powder to transfers. The process starts by allowing the printed film to sit for about 60 to 90 seconds after printing, giving the ink time to become tacky rather than wet. Once the ink reaches the right consistency, the film is placed ink-side up in a large tray. A generous amount of adhesive powder is poured directly onto the design. Using both hands, the user gently lifts and tilts the film, rolling the powder back and forth to ensure full coverage of the printed areas. This step may be repeated several times for even application. To finish, the excess powder is removed by flicking the back of the film until no more powder falls off. When done correctly, hand powdering provides strong adhesion and ensures the durability of the final transfer.

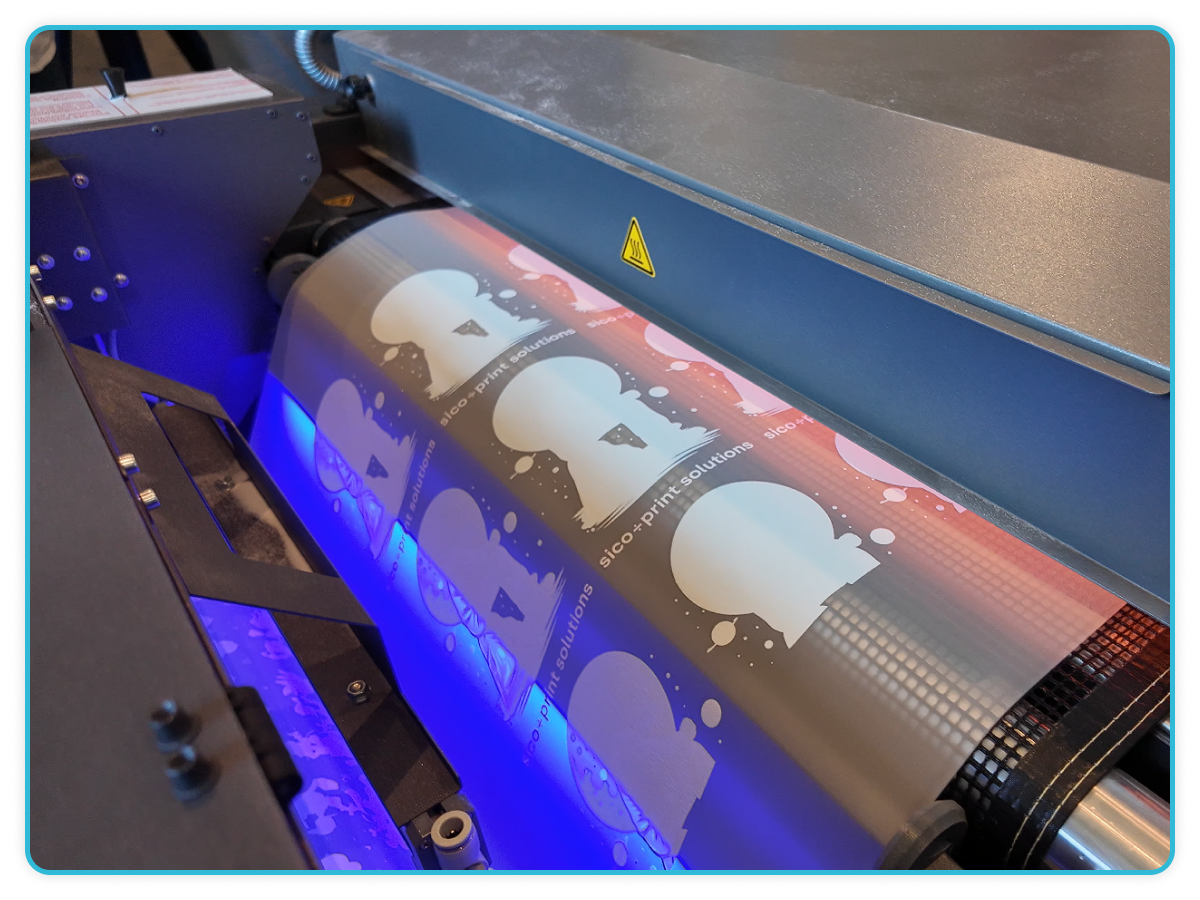

How Automated Powdering Machines Work

Automated powdering machines, often in the form of a dryer–shaker combo unit, offer a faster, cleaner, and more efficient solution for applying adhesive powder to DTF transfers, especially when working with larger batches. The process begins as the printed film passes through the machine’s chamber, where a controlled amount of powder is automatically dispensed onto the design. The powder adheres to the inked areas of the film. Next, the film moves into a drying section equipped with a shaking mechanism. This shaker removes any excess powder while simultaneously initiating the drying process, ensuring an even, consistent application. The result is a clean, ready-to-press transfer with minimal manual effort and maximum precision.